This paper delves deeply into the innovative realm of integrating human emotions with wearable technology. The primary focus is on the conceptualization and development of a kiss transfer device that harnesses the power of wearable technology to bridge the physical gap in human-human interactions. By investigating the intricate nuances of the human-human kissing process, the research seeks to replicate this intimate gesture through a technological medium. The paper not only elaborates on the anatomy, evolution, and hormonal dynamics of kissing but also underscores the transformative potential of wearable technology in capturing and transmitting these intimate moments. This exploration opens up new horizons for long-distance relationships, offering a tangible touchpoint that goes beyond traditional communication methods. Through this pioneering work, the research positions wearable technology as not just a tool for communication but as an extension of our human emotions and expressions.

Research progress of flexible sensor and its interaction technology in force feedback electronic clothing

Vol 2, Issue 2, 2021

Download PDF

Abstract

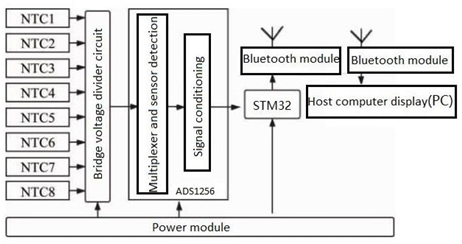

The sense in simulated reality is the key of human-computer interaction technology. Force feedback interaction technology is an important factor to realize simulated force sense in virtual reality. It can truly reproduce the physical information such as the mass, inertia and hardness of things in the virtual world. This paper summarizes the flexible sensors commonly used in force feedback technology and the development and research status of virtual reality wearable electronic clothing equipment based on force feedback technology, summarizes the principles of several force feedback structures, analyzes and compares their characteristics and main application fields. This paper briefly describes the prospect of force feedback technology, summarizes the trend of high-precision, multi-modal and multi-point interaction of force feedback equipment in the future, and puts forward some suggestions on miniaturization, softness and authenticity of force feedback technology in combination with the application characteristics of wearable electronic clothing.

Keywords

References

- Farringdon J, Tilbury N, Church J, et al (editors). Wearable sensor badge sensor jacket for context awareness. Third International Symposium on Wearable Computers; 1999 Oct 18–19; San Francisco: IEEE; p. 107–113.

- De Rossi D, Della Santa A, Mazzoldi A. Dressware: Wearable hardware. Materials Science and Engineering 1999; 7(1): 31–35.

- Feng J, Xia Y, Mei H, et al. Alternating current characteristics of flexible pressure sensor based onnano-carbon black/silicone rubber (in Chinese). Journal of Jilin University (Science Edition) 2014; 52(6): 1311–1315.

- Park J, Lee Y, Hong J, et al. Tactile-direction-sensitive and stretchable electronic skins based on human-skin-inspired interlocked microstructures. ACS Nano 2014; 8(12): 12020–12029.

- Shirinov AV, Schomburg WK. Pressure sensor from a PVDF film. Sensors and Actuators A: Physical 2008; 142(1): 48–55.

- Drean E, Schacher L, Bauer F, et al. A smart sensor for induced stress measurement in automotive textiles. Journal of the Textile Institute 2007; 98(6): 523–531.

- Liu J, Lockhart TE, Jones M, et al. Local dynamic stability assessment of motion impaired elderly using electronic textile pants. IEEE Transactions on Automation Science and Engineering 2008; 5(4): 696–702.

- Persano L, Dagdeviren C, Su Y, et al. High-performance piezoelectric devices based on aligned arrays of nanofibers of poly (vinylidenefluoride-co-trifluoroethylene). Nature Communications 2013; 4(3): 1633.

- Sergio M, Manaresi N, Campi F, et al. A dynamically reconfigurable monolithic CMOS pressure sensor for smart fabric. IEEE Journal of Solid-state Circuits 2003; 38(6): 966–975.

- Meyer J, Lukowicz P, Troster G (editors). Textile pressure sensor for muscle activity and motion detection. 10th IEEE International Symposium on Wearable Computers; 2006 Oct 11–14; Montreux: IEEE; p. 69–72.

- Donselaar R, Chen W (editors). Design of a smart textile mat to study pressure distribution on multiple foam material configurations. 4th International Symposium on Applied Sciences in Biomedical and Communication Technologies. Barcelona: ACM Press International Symposium, 1–5. (2011)

- Rothmaier M, Selm B, Spichtig S, et al. Photonic textiles for pulse oximetry. Optics Express 2008; 16(17): 12973–12986.

- Wijesiriwardana R. Inductive fiber-meshed strain and displacement transducers for respiratory measuring systems and motion capturing systems. IEEE Sensors Journal 2006; 6(3): 571–579.

- Liu G, Wu D, Mei Z, et al. Dynamic respiratory monitoring system based on body area networks (in Chinese). Chinese Journal of Biomedical Engineering 2012; 31(2): 316–319.

- Lin H, Chen D. Design research of bionicmanipulator based on force feedback data glove control (in Chinese). Electromechanical Technology 2018; (1): 7–9.

- Zheng S, Wang A, Dai J. Magnetorheological fluid device and the application in force feedback data gloves (in Chinese). Sensor World 2008; (4): 17–22.

- Frisoli A, Simoncini F, Bergamasco M, et al. Kinematic design of a two contact points haptic interface for the thumb and index fingers of the hand. Journal of Mechanical Design 2007; 129(5): 520–529.

- Dai J, Wang A, Song A, et al. Passive force actuator for force feedback data glove (in Chinese). Journal of Southeast University (Natural Science) 2010; 40(1): 123–127.

- Wang A, Dai J. A passive force feedback data glove based on a smart material (in Chinese). Measurement and Control Technology 2007; 26(11): 10–12.

- Zheng S. Development of force/tactile feedback data gloves based on intelligent materials [PhD thesis]. Nanjing: Southeast University; 2007.

- Wang L. Study on a new magnetorheological damper applied to force feedback data gloves [PhD thesis]. Nanjing: Southeast University; 2011.

- Wang H, Du H, Xiong W, et al. Design and verification of a pneumatic force feedback data glove (in Chinese). Journal of Computer-Aided Design and Computer Graphics 2012; 24(11): 1493–1499.

- Bouzit M, Burdea G, Popescu G, et al. The rutgers master ii-new design force-feedback glove. IEEE/ASME Transactions on Mechatronics 2002; 7(2): 256–263.

- Kopecny L (editor). Producing of tactile feedback via pneumatic muscles. IEEE International Conference on Industrial Technology; 2003; Maribor: IEEE; p. 685–687.

- Sun Z, Bao G, Li X. Force display of soft object of force feedback data gloves based on pneumaticartificial muscle (in Chinese). Journal of Nanjing University of Science and Technology (Natural Science) 2009; 33(6): 713–716.

- Asamura N, Tomori N, Shinoda H (editors). A tactile feeling display based on selective stimulation to skin receptors. Virtual Reality Annual International Symposium; 1998; Atlanta: IEEE; p. 36–42.

- Yuan K, Zhu H, Du Q. A virtual reality system contacts interaction interface (in Chinese). Chinese Journal of Stereology and Image Analysis 2001; 6(3): 153–156.

- Li J, Qi Y, Wang X, et al. A review of the research and applications of force feedback devices based on virtual reality (in Chinese). Mechanical Science and Technology for Aerospace Engineering 2011; 30(7): 1107–1111.

- Liu L, Li W, Dai J. Haptic technology and its application in education and teaching (in Chinese). Digital Education 2017; 3(2): 34–41.

- Li B. Research on hand force feedback device and system [PhD thesis]. Nanjing: Southeast University; 2016.

- Yang L. Research on robot teleoperation system based on force feedback [PhD thesis]. Guangzhou: South China University of Technology; 2011.

- Lu X, Chen X, Sun H, et al. Haptic rendering methods for natural human-computer interaction: A review (in Chinese). Chinese Journal of Scientific Instrument 2017; 38(10): 2391–2399.

Supporting Agencies

Copyright (c) 2021 Ke Dong, Ling Zhang, Jiaxuan Fan, Mengjie Li, Lin Mei, Xueliang Xiao

This work is licensed under a Creative Commons Attribution 4.0 International License.

Prof. Zhen Cao

College of Information Science & Electronic Engineering, Zhejiang University

China, China

Processing Speed

-

-

-

- <5 days from submission to initial review decision;

- 62% acceptance rate

-

-

Asia Pacific Academy of Science Pte. Ltd. (APACSCI) specializes in international journal publishing. APACSCI adopts the open access publishing model and provides an important communication bridge for academic groups whose interest fields include engineering, technology, medicine, computer, mathematics, agriculture and forestry, and environment.