Asia Pacific Academy of Science Pte. Ltd. (APACSCI) specializes in international journal publishing. APACSCI adopts the open access publishing model and provides an important communication bridge for academic groups whose interest fields include engineering, technology, medicine, computer, mathematics, agriculture and forestry, and environment.

Chemical sensors: From fundamentals to the future—A review

Vol 5, Issue 2, 2024

Download PDF

Abstract

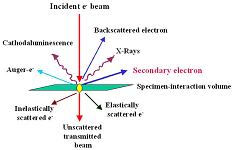

Chemical sensors bridge the gap between the chemical and electrical/optical domains, offering a powerful tool for analyzing our environment. These ingenious devices, with detection limits reaching parts-per-billion (ppb) for some analytes, rely on interactions between a specific material and the target molecule. This interaction, which can involve changes in electrical current, light emission, or mass, is translated into a measurable signal. This review delves into the core working principles of various sensor types, highlighting their diverse applications. From environmental monitoring (tracking air and water pollutants at concentrations as low as 10 ppb) to medical diagnostics (detecting biomarkers for early disease identification), chemical sensors play a crucial role in shaping a safer and healthier future. Recent advancements, such as miniaturization and integration with nanomaterials, promise even greater sensitivity, portability, and affordability, paving the way for a new era of sensor-driven innovation. This review article explores these advancements and their potential impact on various fields, inspiring further development and exploration of this transformative technology.

Keywords

References

- Korotcenkov G, Cho BK. Introduction to Chemical Sensor Technologies. Chemical Sensors: Comprehensive Sensor Technologies. Momentum Press; 2011.

- Janata J. Chemical sensors. Analytical Chemistry. 1992; 64(12): 196–219. doi: 10.1021/ac00036a012

- Paolesse R, Nardis S, Monti D, et al. Porphyrinoids for chemical sensor applications. Chemical Reviews. 2017; 117(4): 2517–2583.

- Mimendia A, Gutiérrez JM, Leija L, et al. A review of the use of the potentiometric electronic tongue in the monitoring of environmental systems. Environmental Modelling & Software. 2010; 25(9): 1023-1030. doi: 10.1016/j.envsoft.2009.12.003

- Janata J. Principles of Chemical Sensors. Springer US; 2009.

- Cammann K, Lemke U, Rohen A, et al. Chemical sensors and biosensors—principles and applications. Angewandte Chemie International Edition in English. 1991; 30(5): 516–539.

- Banica FG. Chemical sensors and biosensors: fundamentals and applications. John Wiley & Sons; 2012.

- Wang J. Electrochemical transduction. Handbook of Chemical and Biological Sensors; 1996. doi: 10.1201/9781420050486.ch5

- Vlasov YG, Ermolenko YE, Legin AV, et al. Chemical sensors and their systems. Journal of Analytical Chemistry. 2010; 65: 880–898.

- Stetter JR, Penrose WR, Yao S. Sensors, Chemical Sensors, Electrochemical Sensors, and ECS. Journal of the Electrochemical Society. 2003; 150(2): S11. doi: 10.1149/1.1539051

- Bakker E, Telting-Diaz M. Electrochemical Sensors. Analytical Chemistry. 2002; 74(12): 2781–2800. doi: 10.1021/ac0202278

- Lobnik A, Turel M, Urek SK. Optical chemical sensors: design and applications. Advances in chemical sensors. 2012; 3(5).

- Wolfbeis OS. Fiber-Optic Chemical Sensors and Biosensors. Analytical Chemistry. 2006; 78(12): 3859–3874. doi: 10.1021/ac060490z

- Gauglitz G. Direct optical sensors: principles and selected applications. Analytical and Bioanalytical Chemistry. 2005; 381(1): 141–155. doi: 10.1007/s00216-004-2895-4

- Gründler P. Mass-sensitive sensors. Chemical Sensors: An Introduction for Scientists and Engineers; 2007. 119–122.

- Fischerauer G, Dickert FL. An analytic model of the dynamic response of mass-sensitive chemical sensors. Sensors and Actuators B: Chemical. 2007; 123(2): 993-1001. doi: 10.1016/j.snb.2006.11.002

- Li D, Hu J, Wu R, et al. Conductometric chemical sensor based on individual CuO nanowires. Nanotechnology. 2010; 21(48): 485502. doi: 10.1088/0957-4484/21/48/485502

- Steinberg MD, Žura I, Murkovic Steinberg I. Wireless smart tag with on-board conductometric chemical sensor. Sensors and Actuators B: Chemical. 2014; 196: 208–214. doi: 10.1016/j.snb.2014.02.012

- Carey WP, Kowalski BR. Chemical piezoelectric sensor and sensor array characterization. Analytical Chemistry. 1986; 58(14): 3077–3084. doi: 10.1021/ac00127a037

- Tressler JF, Alkoy S, Newnham RE. Piezoelectric sensors and sensor materials. J Electroceram. 1998; 2: 257–272.

- Yaroshenko I, Kirsanov D, Marjanovic M, et al. Real-Time Water Quality Monitoring with Chemical Sensors. Sensors. 2020; 20(12): 3432. doi: 10.3390/s20123432

- Kruse P. Review on water quality sensors. Journal of Physics D: Applied Physics. 2018; 51(20): 203002. doi: 10.1088/1361-6463/aabb93

- Pérez-Gómez A. Attunement: Architectural meaning after the crisis of modern science. Mit Press; 2016.

- Yao J, Yang M, Duan Y. Chemistry, Biology, and Medicine of Fluorescent Nanomaterials and Related Systems: New Insights into Biosensing, Bioimaging, Genomics, Diagnostics, and Therapy. Chemical Reviews. 2014; 114(12): 6130–6178. doi: 10.1021/cr200359p

- Zhang X, Ju H, Wang J. Electrochemical sensors, biosensors and their biomedical applications. Academic Press; 2011.

- Yang F, Yao J, Zheng F, et al. Guarding food safety with conventional and up-conversion near-infrared fluorescent sensors. Journal of Advanced Research. 2022; 41: 129–144. doi: 10.1016/j.jare.2022.01.011

- Baraton MI. Sensors for environment, health and security: advanced materials and technologies. Springer Science & Business Media; 2008.

- El-Safty SA, Shenashen MA. Nanoscale dynamic chemical, biological sensor material designs for control monitoring and early detection of advanced diseases. Materials Today Bio. 2020; 5: 100044. doi: 10.1016/j.mtbio.2020.100044

- Philippe C, Anastasia M, Anastasios K, et al. Improving water quality and security with advanced sensors and indirect water sensing methods. Instrumentation and Measurement Technologies for Water Cycle Management. Springer; 2022. 251–277.

- Aravindan M, Madhan Kumar V, Hariharan VS, et al. Fuelling the future: A review of non-renewable hydrogen production and storage techniques. Renewable and Sustainable Energy Reviews. 2023; 188: 113791. doi: 10.1016/j.rser.2023.113791

- Aravindan M, Praveen Kumar G. Hydrogen towards sustainable transition: A review of production, economic, environmental impact and scaling factors. Results in Engineering. 2023; 20: 101456. doi: 10.1016/j.rineng.2023.101456

- Aravindan M, Madhesh K, Praveen Kumar G, et al. Computational and Chemical Kinetics Analysis of Hydrogen-Blended LPG for Domestic Cook Stove Burners. Energy Conversion and Management: X. 2024; 22: 100568. doi: 10.1016/j.ecmx.2024.100568

- Marimuthu A, Govindasamy PK. Driving an ecological transformation: unleashing multi-objective optimization for hydrogenated compressed natural gas in a decarbonization perspective. Environmental Science and Pollution Research. 2024; 31(21): 31632-31645. doi: 10.1007/s11356-024-33396-6

- Aravindan M, Praveen Kumar G. Optimizing novel green hydrogen production from solar and municipal solid waste: A thermo-economic investigation with environmental comparison between integrated low temperature power cycles. Process Safety and Environmental Protection. 2024; 186: 421–447. doi: 10.1016/j.psep.2024.03.085

- Aravindan M, Praveen Kumar G, Arulanandam MK, et al. Multi-objective optimization and analysis of chemical kinetics properties: Exploring the impact of different hydrogen blending ratios on LPG and methane-air mixtures. Energy Conversion and Management: X. 2024; 22: 100532. doi: 10.1016/j.ecmx.2024.100532

- Aravindan M, Praveen Kumar G, Muthaiah R, et al. Unlocking clean gas with hydrogen: A combustion optimization study. Results in Engineering. 2024; 23: 102363. doi: 10.1016/j.rineng.2024.102363

- Fang L, Jia M, Zhao H, et al. Molecularly imprinted polymer-based optical sensors for pesticides in foods: Recent advances and future trends. Trends in Food Science & Technology. 2021; 116: 387-404. doi: 10.1016/j.tifs.2021.07.039

Supporting Agencies

Copyright (c) 2024 Tony Richard, Shiny Climensa

License URL: https://creativecommons.org/licenses/by/4.0/

This site is licensed under a Creative Commons Attribution 4.0 International License (CC BY 4.0).

1.jpg)

Prof. Sivanesan Subramanian

Anna University, India

.jpg)