Asia Pacific Academy of Science Pte. Ltd. (APACSCI) specializes in international journal publishing. APACSCI adopts the open access publishing model and provides an important communication bridge for academic groups whose interest fields include engineering, technology, medicine, computer, mathematics, agriculture and forestry, and environment.

Optimizing X-ray fluorescence spectrometry using fusion sample preparation to quantify ten major and minor elements in manganese ores

Vol 4, Issue 2, 2023

Download PDF

Abstract

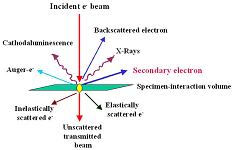

A rapid and straightforward method has been devised for direct analysis of SiO2, Al2O3, Fe, MgO, CaO, K2O, Mn, TiO2, P, and Zn in manganese ore samples using an X-ray fluorescence spectrometer (XRF). The method employs a glass fusion technique with a flux composed of Li2B4O7, LiBO2, and LiF (in a mass ratio of 45:10:5), NH4NO3 as an oxidizing agent, and LiBr as a stripping agent. The method's experimental parameters were fine-tuned, and its performance metrics were assessed. The proposed method was used to analyze the certified reference materials GBW07261 to GBW07266, yielding relative standard deviations (RSD, n = 12) below 2%. Accuracy was verified using synthetic samples, and the obtained results were in line with the certified values.

Keywords

References

- Rock mineral analysis compilation group Rock mineral analysis (Volume II). Beijing: Geological Publishing House; 2011. pp. 804-861.

- Zhu M. Micro exploration of analysis method and application practice of manganese ore composition. China manganese industry. 2017; 35(1): 116-118.

- Zhou W, Zhang N, Zhao Z, et al. Determination of manganese in manganese ore leaching solution containing a large amount of iron (Ⅱ) by potassium periodate oxidation spectrophotometry. Metallurgical analysis. 2013; 33(2): 47-50.

- Zhang Q, Deng J, Wang Y, et al. Rapid determination of silicon dioxide content in manganese ore by volumetric method. China manganese industry. 2012; 30(1): 41-43.

- Jiao L, Li H. Determination of silicon dioxide content in manganese ore by ICP-AES. Spectrum Laboratory. 2007; 24(3): 360-362.

- Tang M, Li X, Wei Y, et al. Determination of primary and secondary components in sintered manganese ore by X- ray fluorescence spectrometry. Spectral laboratory. 2012; 29(2): 977-981.

- Liu J, Dang L, Zhen Y. Determination of 17 primary and secondary components in manganese ore by melting sample preparation X-ray fluorescence spectrometry. Metallurgical analysis. 2013; 33(9): 37-41.

- Liu J, Zhu J. Rapid determination of primary and secondary components in manganese ore by X-ray fluorescence spectrometry. Analytical testing technology and instrument. 2012; 18(1): 34-37.

- Qu Y, Wang Y, Zhang Q, et al. Determination of 9 components in manganese ore by melting sample preparation—X-ray fluorescence spectrometry. Metallurgical analysis. 2011; 31(9): 24-29.

- Wang Q, Lin L, Zhu L, et al. Applied theory α Matrix effect in the analysis of manganese ore by coefficient corrected X-ray fluorescence spectrometry. Physical and chemical inspection (chemical volume). 2008; 44(7): 658-660.

- Li X. Determination of major and minor elements in manganese ore samples by melt sectioning X-ray fluorescence spectrometry. Rock and mineral testing. 2007; 26(3): 238-240.

- Ma J, Liu H, Wang F. Melting sample preparation—Determination of primary and secondary components in Geological Samples by X-ray fluorescence spectrometry. Analysis laboratory. 2016; 35(11): 1348-1352.

- Ma J, Jia H, Lan L, et al. Determination of major and minor elements in silica by X-ray fluorescence spectrometry. China Inorganic analytical chemistry. 2017; 7(2): 55-58.

Supporting Agencies

Copyright (c) 2023 Jingzhi Ma

This work is licensed under a Creative Commons Attribution 4.0 International License.

This site is licensed under a Creative Commons Attribution 4.0 International License (CC BY 4.0).

1.jpg)

Prof. Sivanesan Subramanian

Anna University, India

.jpg)