Asia Pacific Academy of Science Pte. Ltd. (APACSCI) specializes in international journal publishing. APACSCI adopts the open access publishing model and provides an important communication bridge for academic groups whose interest fields include engineering, technology, medicine, computer, mathematics, agriculture and forestry, and environment.

Characterization of Ecuadorian feldspar by instrumental analytical techniques and statistical calculation of uncertainty for the reliability of results

Vol 4, Issue 1, 2023

Download PDF

Abstract

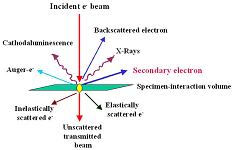

The present study has as objective the analysis and characterization of a sample of an Ecuadorian feldspar, by means of XRD, SEM and TGA techniques, for the microstructural analysis of mineral phase and chemical composition. Qualitative and quantitative X-ray diffraction analysis by Rietveld refinement revealed that this feldspar is composed of 33.31% Albite, 15.70% Quartz and a large percentage by weight of 50.99% amorphous material. To validate these results, the uncertainty of the measurement was investigated and calculated by statistical analysis of standard deviation, giving as results an uncertainty error of ±0.87 wt%, ±0.23 wt% and ±0.89 wt% respectively for the percentages by weight of the minerals found in this analysis. The result by SEM shows the presence of Albite in the feldspar exhibiting laminar twinning and characterized by randomly dispersed spherical quartz and plagioclase inclusions.

Keywords

References

- Parsons I, Fitz Gerald JD, Lee MR. Routine characterization and interpretation of complex alkali feldspar intergrowths. American Mineralogist. 2015; 100(5-6): 1277-1303. doi: 10.2138/am-2015-5094

- Rietveld HM. The Rietveld method. Physica Scripta. 2014; 89(9): 098002. doi: 10.1088/0031-8949/89/9/098002

- Toby BH. Rfactors in Rietveld analysis: How good is good enough? Powder Diffraction. 2006; 21(1): 67-70. doi: 10.1154/1.2179804

- McCusker LB, Von Dreele RB., Cox DE, et al. Rietveld refinement guidelines. Journal of Applied Crystallography. 1999; 32(1): 36-50. doi: 10.1107/S0021889898009856

- Toraya H, Marumo F. Preferred orientation correction in powder patternfitting. Mineralogical Journal. 1981; 10(5): 211-221. doi: 10.2465/minerj.10.211

- Ahtee M, Nurmela M, Suortti P, Järvinen M. Correction for preferred orientation in Rietveld refinement. Journal of Applied Crystallography. 1989; 22(3): 261-268. doi: 10.1107/S0021889889000725

- Shim SH, Kim SJ, Ahn JH. Quantitative analysis of alkali feldspar minerals using Rietveld refinement of X-ray diffraction data. American Mineralogist. 1996; 81(9-10): 1133-1140. doi: 10.2138/am-1996-9-1011

- Schwarzenbach D, Abrahams SC, Flack HD, et al. Statisical descriptions in crystallography. II. Report of a Working Group on Expression of Uncertainty in Measurement. Acta Crystallographica Section A Foundations of Crystallography. 1995; 51(4): 565-569. doi: 10.1107/s0108767395002340

- Santana ST, Khoury HJ, Sullasi HL, et al. Luminescence properties of feldspars from the Northeast region of Brazil. Journal of Physics: Conference Series. 2010; 249: 012028. doi: 10.1088/1742-6596/249/1/012028

- Hradil D, Bezdička P, Hradilová J, Vašutová V. Microanalysis of clay-based pigments in paintings by XRD techniques. Microchemical Journal. 2016; 125: 10-20. doi: 10.1016/j.microc.2015.10.032

- Yuan B, Li C, Liang B, et al. Extraction of potassium from K-feldspar via the CaCl2 calcination route. Chinese Journal of Chemical Engineering. 2015; 23(9): 1557-1564. doi: 10.1016/j.cjche.2015.06.012

- Speakman SA. Introduction to PANalytical X’Pert HighScore Plus v3.0. PANalytical; 2012.

- Ellison S, Rosslein M, Williams A. EURACHEM/CITAC Guide: Quantifying Uncertainty in Analytical Measurement. Journal of Analytical Chemistry. 2002; 58(2): 191-191. doi: 10.1023/A:1022374509064

- Lewandowski CM, Co-investigator N, Lewandowski CM. Measurement Uncertainties/Physical Parameters and Calibration of Instruments. In: The effects of brief mindfulness intervention on acute pain experience: An examination of individual difference. Elsevier; 2015.

- Joint Committee for Guides in Metrology. Evaluation of measurement data-An introduction to the “Guide to the expression of uncertainty in measurement” and related documents. Joint Committee for Guides in Metrology; 2009. p. 28. doi: 10.1016/0263-2241(85)90006-5

- Joint Committee for Guides in Metrology (JCGM). Evaluation of measurement data: Guide to the expression of uncertainty in measurement. Joint Committee for Guides in Metrology; 2008. p. 120.

- Bell S. A Beginner’s Guide to Uncertainty of Measurement. Measurement Good Practice Guide. 1999; (2): 41.

Supporting Agencies

Copyright (c) 2023 Monica Moreno-Barriga, Andrés Noguera-Cundar, Lidia Castro-Cepeda

This work is licensed under a Creative Commons Attribution 4.0 International License.

This site is licensed under a Creative Commons Attribution 4.0 International License (CC BY 4.0).

1.jpg)

Prof. Sivanesan Subramanian

Anna University, India

.jpg)